SEE HOW YOUR FAVORITE PAIR OF ZISH IS MADE !!!

Design Conceptualization

The process begins with the conceptualization of new designs. Zish footwear designers research market trends, gather inspiration from various sources such as fashion shows, street styles, and cultural influences, and sketch out potential designs.

Material Selection

Once the designs are finalized, the next step is to select the materials that will be used for the footwear. Zish focuses on using high-quality materials that not only provide comfort but also ensure durability and style. Common materials include leather, suede, synthetic fabrics, rubber, and various types of embellishments like buckles, beads, sequins, and embroidery.

Pattern Making

Skilled pattern makers then create the patterns based on the finalized designs. These patterns serve as templates for cutting the materials and assembling the footwear. Precision and attention to detail are crucial in this stage to ensure that the final product fits well and looks aesthetically pleasing.

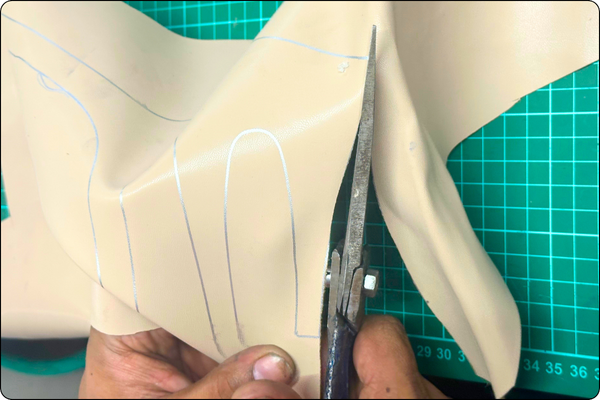

Cutting

Once the patterns are ready, the selected materials are laid out and cut according to the patterns. Cutting is done with precision to minimize waste and maximize material utilization. Different components of the footwear, such as the upper, lining, insole, and outsole, are cut separately.

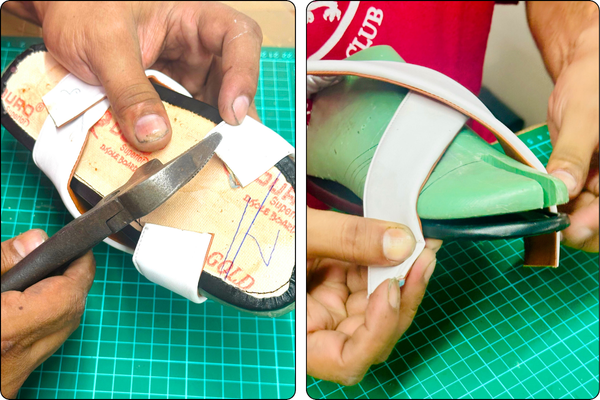

Assembly / Stitching

The cut pieces are then assembled together by skilled craftsmen and women. Depending on the design, assembly may involve stitching, gluing, or both. This process requires meticulous attention to detail to ensure that all components are aligned correctly and securely fastened.

Lasting

Lasting is the process of shaping the upper part of the footwear around a mold called a last. The last determines the size, shape, and fit of the footwear. It helps in achieving the desired shape and structure of the final product. Lasting can be done manually or with the help of machinery, depending on the complexity of the design.

Sole Attachment

Once the upper is properly shaped and assembled, the outsole is attached to the bottom of the footwear. This step is crucial for providing traction, support, and durability. Various techniques such as stitching, cementing, or molding may be used to attach the outsole securely to the upper.

Finishing Touches

After the sole attachment, the footwear goes through a series of finishing touches. This may include polishing, buffing, trimming excess materials, adding embellishments, and quality checks to ensure that the final product meets Zish's standards of quality and aesthetics.

Quality Control

Before packaging and shipping, every pair of Zish footwear undergoes rigorous quality control checks. This involves inspecting for any defects, flaws, or inconsistencies in stitching, materials, and overall construction. Only products that pass these quality checks are deemed ready for sale.

Packaging and Shipping

Finally, the finished footwear is carefully packaged in boxes or bags, along with any accompanying accessories or promotional materials. Zish ensures that the packaging not only protects the footwear during transit but also reflects the brand's image and values. The products are then shipped to retailers, wholesalers or directly to customers, ready to be worn and enjoyed.

Throughout the entire process, Zish maintains a commitment to craftsmanship, quality, and innovation, ensuring that every pair of footwear embodies the brand's vision of style, comfort, and elegance for women.